The crown cap is a versatile product that can be used for beverages such as beer, juice, sparkling water, etc.

Customized design beer glass bottle crown cap

Product Name:Customized design beer glass bottle crown cap

The crown cap is a versatile product that can be used for beverages such as beer, juice, sparkling water, etc. Belongs to standard size, the pattern is beautifully printed, and can be customized as required. Product quality first, short delivery time.

Material Analysis

Chrome-plated plate and method for producing the same, and method for producing a crown cover.

The manufacturing method includes the steps of: steel making, hot rolling, pickling cold rolling, continuous annealing and leveling. In the present invention, the annealing temperature in the continuous withdrawal process is adjusted, so that the cold-rolled sheet is in an intermediate annealing state, and part of the unrecrystallized structure is retained. In this way, the strength level of the strip is guaranteed, and at the same time, the strip has a certain elongation rate to ensure its deformation ability during the stamping process.

[Patent Description]

Chrome-plated plate and method of making the same, crown cover

technical field

The invention belongs to milk steel technical field, be specifically related to a kind of chrome plate and manufacture method thereof, crown cover.

[Background technique]

Due to having good sealing performance, crown cap can keep pressure and quality and taste unchanged for a long time, so it is widely used in industries such as beer and carbonated beverages packed in glass bottles, and wherein beer industry is the main. The crown cover is a stamped tinplate, generally made of T4 material with a thickness of 0.22~0.24mm and a hardness of HR30Tm of 61 ± 3. There are two types of surface plating: tin plating (SPTE) and chrome plating (TFS). With the development of the food packaging industry, it is proposed to reduce the thickness of the crown cover, increase the strength, and use low-cost chrome plating (TFS) instead of tin plating.

Metal printing is rarely the printing of final products, but is often an integral part of the processing process of various containers, covers, building materials, household electrical appliances, furniture, nameplates and various miscellaneous supplies. life is the main purpose. Therefore, in order to arouse consumers' desire to buy and improve the sales value of commodities, as a means of promotion, novel binding designs and exquisite printing should be carried out. In this way, metal printing becomes more important.

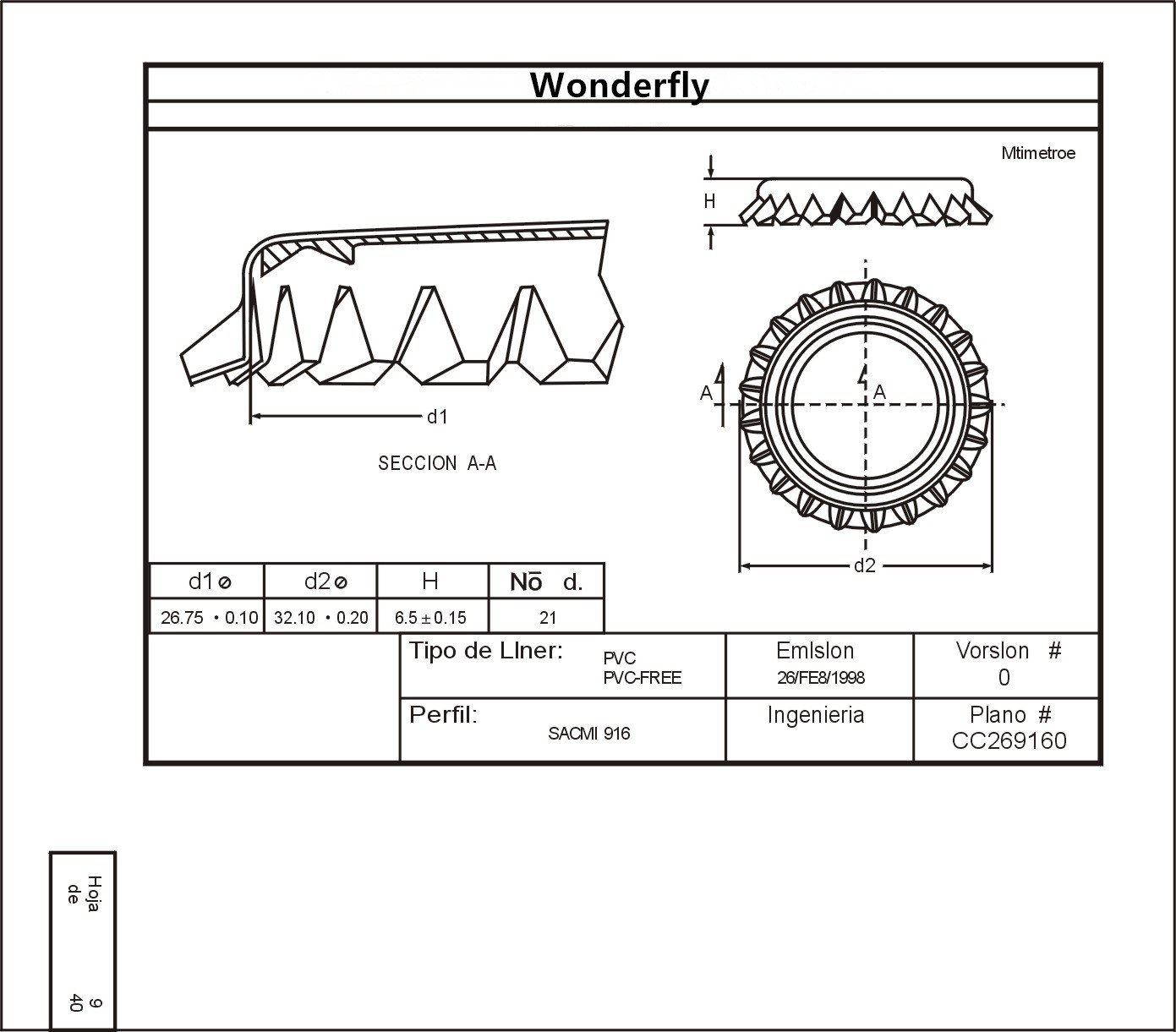

| Name of the product | crown cap | Number of Flutes | 21 | |

| Liner | PE | Pieces per Carton | 10000 | |

| Material | Tinplate and ferrochrome plated | Carton Weight (KG) | 25 | |

| Inner Dia(min.) (mm) | 26.75±0.03 | Carton Dimension | 55*35*30cm | |

| Cap Height (mm) | 6.00±0.07 | Type of printing | Customize colors | |

| Out Dia.(mm) | 32.10±0.20 | Packaging | White poly bag , then packed in carton . | |

| Usage | Bottles.beer,Water.Juice,soft drink | Feature | Non Spill | |

| Customized Order | Accept | Place of Origin: | Shandong,China | |

| Brand Name | Wonderfly | Model Number | WDF-02 | |

| Color | Customized | Size | 26mm | |

| Application | Bottle usage | MOQ | Pure color:100,000pcsCustom logo:300,000pcs | |

| Logo | Custom logo | Sample | provided | |

| Packaging&delivery | Packaging Detail.10,000 pcs /carton . First , white poly bag ,then packed in carton . | |||

| Port | Qingdao,Tianjin | |||

Lead Time

| Quantity(pieces) | 1 - 100000 | >100000 |

| Est. time (days) | 7 | To be negotiated |

Metal printed products should generally have the following characteristics:

①Bright colors, rich layers, and good visual effects: If the metal material is chrome-plated steel, because the surface is chrome-plated, it has a flashing color effect.

②Good processability of printing materials and diversity of modeling design; metal printing materials have good mechanical properties, processing and molding properties, and metal packaging containers can realize novel and unique modeling designs, and produce various special-shaped cylinders, cans, boxes. and other packaging containers, to achieve the purpose of beautifying the commodity and improving the competitiveness of the commodity;

③ Conducive to the realization of the use value and artistry of the commodity: the good performance of the metal material and the good wear resistance and durability of the printing ink not only create conditions for the realization of unique design and exquisite printing, but also improve the durability of the commodity. It can better reflect the use value and artistry of commodities.

The production process and quality of the crown cap:

Bottle caps: Bottle caps are bottle caps with sizes, materials of various sizes, bulking, and liner processing to form a bottle cap with a certain outer diameter, height, and skirt teeth.

We can provide FREE samples. The number of samples we provide is sufficient to test the quality of the product. Normally it takes 1 days to finish the samples. The sample delivery time around 3-5days.

We can provide FREE samples. The number of samples we provide is sufficient to test the quality of the product. Normally it takes 1 days to finish the samples. The sample delivery time around 3-5days.