The crown cap is a versatile product that can be used for beverages such as beer, juice, sparkling water, etc.

Pure color beer crown cap 26mm

The crown cap is a versatile product that can be used for beverages such as beer, juice, sparkling water, etc. Belongs to standard size, the pattern is beautifully printed, and can be customized as required. Product quality first, short delivery time.

Pure color beer crown cap.

Material Analysis

Materials for bottle cap production: iron plates, various coating materials, printing inks, liner materials, etc. are processed and combined.

Iron: is the main material of the cap shell

Coating: It protects metal materials from scratches and corrosion

Printing ink: it is the carrier for presenting text, patterns, categories and publicity activities

Liner material: is the sealing material of the bottle cap

[Background technique]

Due to having good sealing performance, crown cap can keep pressure and quality and taste unchanged for a long time,so it is widely used in industries such as beer and carbonated beverages packed in glass bottles, and wherein beer industry is the main. The crown cover is a stamped tinplate, generally made of T4 material with a thickness of 0.22~0.24mm and a hardness of HR30Tm of 61 ± 3. There are two types of surface plating: tin plating (SPTE) and chrome plating (TFS). With the development of the food packaging industry, it is proposed to reduce the thickness of the crown cover, increase the strength, and use low-cost chrome plating (TFS) instead of tin plating.

Metal printing is rarely the printing of final products, but is often an integral part of the processing process of various containers, covers, building materials, household electrical appliances, furniture, nameplates and various miscellaneous supplies. life is the main purpose. Therefore, in order to arouse consumers' desire to buy and improve the sales value of commodities, as a means of promotion, novel binding designs and exquisite printing should be carried out. In this way, metal printing becomes more important.

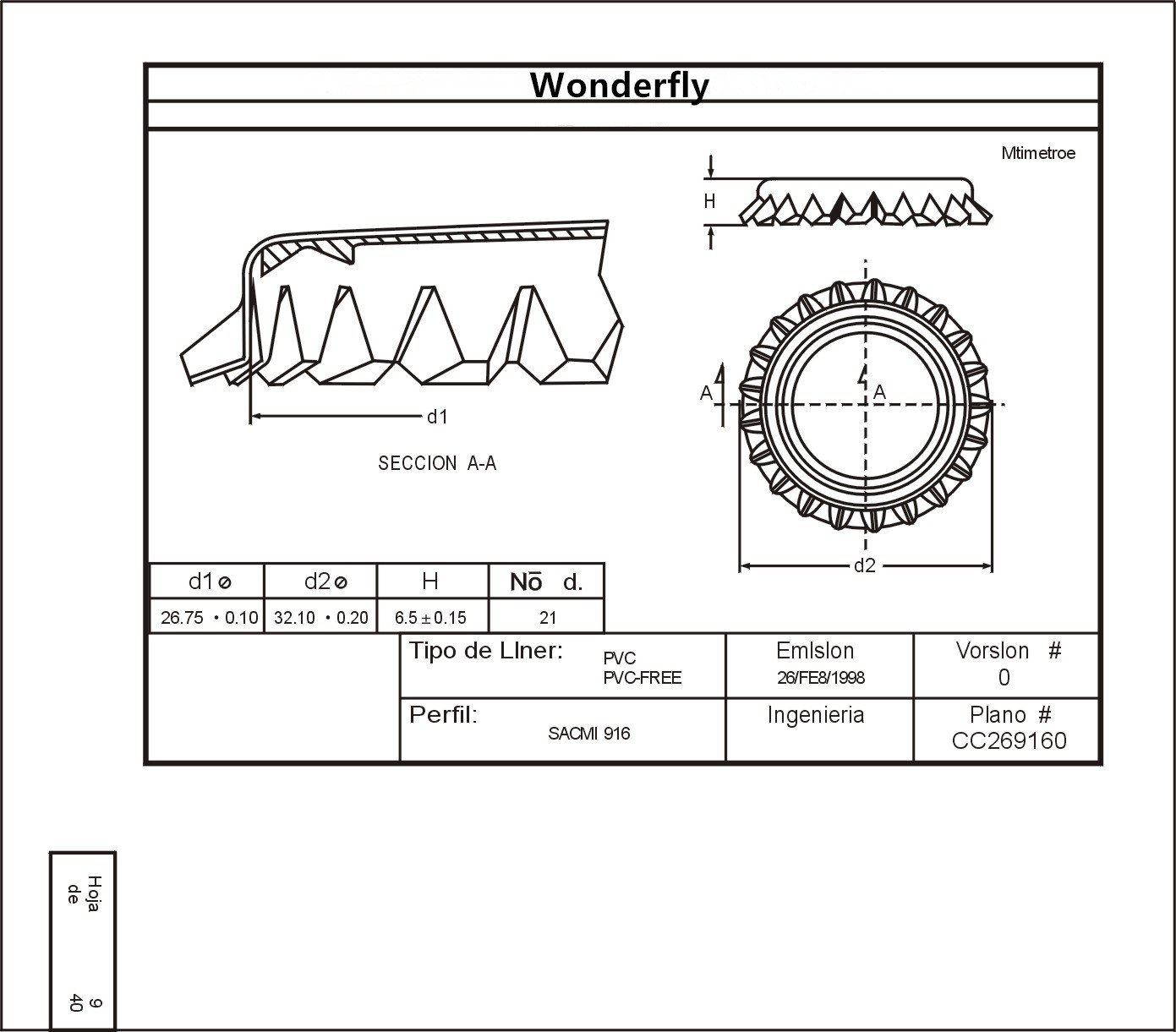

| Name of the product | crown cap | Number of Flutes | 21 | |

| Liner | PE | Pieces per Carton | 10000 | |

| Material | Tinplate and ferrochrome plated | Carton Weight (KG) | 25 | |

| Inner Dia(min.) (mm) | 26.75±0.03 | Carton Dimension | 55*35*30cm | |

| Cap Height (mm) | 6.00±0.07 | Type of printing | Customize colors | |

| Out Dia.(mm) | 32.10±0.20 | Packaging | White poly bag , then packed in carton . | |

| Usage | Bottles.beer,Water.Juice,soft drink | Feature | Non Spill | |

| Cutomized Order | Accept | Place of Origin: | Shandong,China | |

| Brand Name | Wonderfly | Model Number | WDF-02 | |

| Color | Customized | Size | 26mm | |

| Application | Bottle usage | MOQ | Pure color:100,000pcsCustom logo: 300,000pcs | |

| Logo | Custom logo | Sample | provided | |

| Packaging&delivery | Packaging Detail.10,000 pcs /carton . First , white poly bag ,then packed in carton . | |||

| Port | Qingdao,Tianjin | |||

Lead Time

| Quantity(pieces) | 1 - 100000 | >100000 |

| Est. time (days) | 7 | To be negotiated |

The PE liner pellet for crown cover is made up of PE resin and auxiliary materials such as food-grade elastic polymer. It is non-toxic and tasteless, does not contain any plasticizers, and fully meets the requirements of food hygiene and meets EU standards.

②Crown cap pe liner granules, consistent particles, uniform plasticization, good melt fluidity, can form a smooth and flat surface of the bottle gasket after extrusion molding and hot pressing, with good elasticity, good sealing performance, and excellent sealing performance.

③ Good hygiene index, in line with European and American requirements for hygiene performance of food packaging materials, suitable for inner pads of bottle caps such as beer and beverages.

The production process and quality of the crown cap:

Bottle caps: Bottle caps are bottle caps with sizes, materials of various sizes, bulking, and liner processing to form a bottle cap with a certain outer diameter, height, and skirt teeth.

We can provide FREE samples. The number of samples we provide is sufficient to test the quality of the product. Normally it takes 1 days to finish the samples. The sample delivery time around 3-5days.

We can provide FREE samples. The number of samples we provide is sufficient to test the quality of the product. Normally it takes 1 days to finish the samples. The sample delivery time around 3-5days.